Product Lifecycle Management

Have you heard of product lifecycle management (PLM)?

Product Lifecycle Management (PLM) is a series of integrated business systems. These business systems include collaborative creation, management, and dissemination of engineering information. This information begins during a product's conception and spans through the end of life. There are many different tools available that are beneficial for product lifecycle management. Here at Seifert, we use Microsoft tools to help manufacturers with PLM. We help them gain visibility about the products that they produce at any point in the lifecycle. Visibility is crucial, especially when it comes to sales and customer service. Let's dive a little bit deeper.

Understanding Product Lifecycle Management

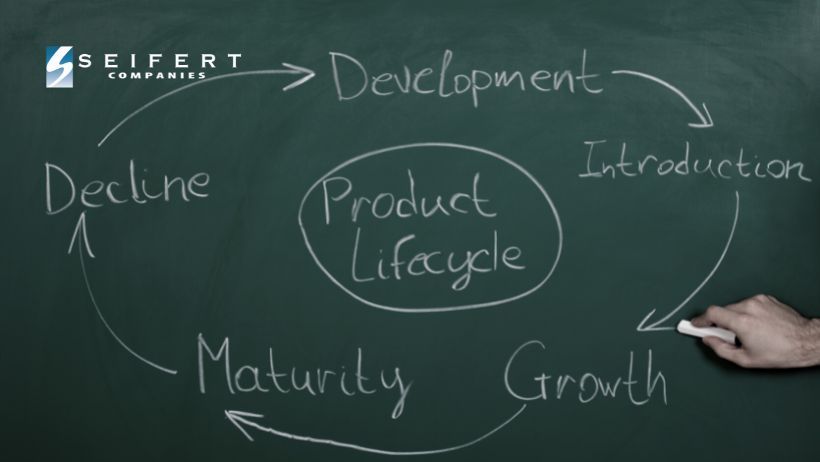

Simplified product lifecycle management is the process of managing a product's lifecycle. PLM follows products through many phases of product life. These include development and introduction, growth, maturity/stability, and decline.

This system focuses on both the manufacturing of the product and its marketing. Companies create products for many reasons, but most have similar goals. They strive to create profitable products that outperform the competition. PLM gives information necessary to know if those goals are being accomplished. It's also beneficial when it comes to managing marketing strategy and engineering challenges. It's a complex process, but it can be simple when you have help. It involves using technology to create, capture, manage, and leverage your products. If utilized, PLM will help your company maximize profits.

The Benefits

The biggest benefit of PLM is simplifying things for manufacturers and businesses. The software makes it easy to track and share data along the product value chain, from initial design through manufacturing, supply chain management and operations, and asset maintenance. There are so many other benefits that product lifecycle management offers alongside simplification. PLM can help companies put out higher quality products and get products out to the market faster. It also improved product safety and increases sales opportunities. A huge benefit is the reduction of errors occurring. This saves both time and money. Computer software is also available to assist with product lifecycle management. Document management, design integration, and process management are possible functions for help.

Other benefits include:

- Improved product quality and reliability.

- Reduced prototyping costs.

- More accurate and timely requests for quote (RFQ), i.e., solicitations from suppliers.

- Quick identification of sales opportunities and revenue contributions.

- Savings through the reuse of original data.

- A framework for product optimization.

- Reduced waste.

- Improved ability to manage seasonal fluctuation.

- Improved forecasting to reduce material costs.

- Maximized supply chain collaboration.

Microsoft Tools and PLM

Here are two tools Microsoft offers that can be beneficial when it comes to PLM approaches:

Microsoft Dynamics 365

Dynamics 365 is a portfolio of intelligent business applications that delivers superior operational efficiency and breakthrough customer experiences enabling businesses to become more agile and reduce complexity without increasing costs. Dynamics offers so many benefits to users. It allows you to adapt and thrive with a digital supply chain. This will enhance your supply chain visibility. It allows you to create a digital supply chain twin. You can unify disparate data sources, improve multi-tier supplier collaboration, and remove stockouts. This reduces risks. It helps improve equipment effectiveness and reduce downtime. You're able to innovate with mixed reality and advanced technology. You can also automate order fulfillment with AI. Finally, you're able to predict disruptions. This helps you overcome them before they happen. Doing this will help meet customer demand. It will also help you stay profitable.

Microsoft Intune

Microsoft Intune is a cloud-based endpoint management solution. It manages user access and simplifies app and device management across your many devices, including mobile devices, desktop computers, and virtual endpoints. There are many benefits of using Intune. You're able to protect access and data on both organization-owned and personal devices. You're able to deploy Microsoft 365 apps to users and devices in your organization. You can also deploy these apps when users sign in for the first time. It brings together device visibility. It also brings you endpoint security and data-driven insights. These will help you increase IT efficiency and improve user experiences.

How It Works

We've already stated above that Seifert utilizes these Microsoft tools for manufacturers. What we didn't do is explain how. Here's an example of how it works. Let's say you want to fulfill an order that came in right now on your website for 1000 widgets.

Scenario #1

Supply chain backlogs postpone production for four months. Using Dynamics 365 and other Microsoft tools, you can see the problem and alert the customer. This allows you to address kinks in production as soon as the order comes through. Without this knowledge base, you may promise an order which you can't fill. This can happen when you leave and only have the supply timeline in your head. Visibility is everything. Being able to communicate with customers as soon as possible is important. They're likely going to be understanding and appreciative of the communication.

Scenario #2

There is a recall on a part that you must now send to every customer that bought your product containing that part. Let's give the example of airbags in cars. Through good tracking in your PLM, you will be able to see who bought the product. You'll also be able to see where you sent the products to and how many are still in your inventory. The goal is to address the issue as quickly as possible. Through PLM, you have the visibility to do that. You want to be able to reach the right customers at the right time to keep them around.

To Conclude

To meet customers' needs, companies need to adapt and respond. When there are disruptions to demand and supply, the goal is to do this as quickly as possible. The best way to do this with success is through supply chain and product visibility.

Microsoft offers tools that take a unique approach to product lifestyle management. These tools can make your PLM approach more productive and efficient than others. Microsoft tools allow us here at Seifert to help you with that approach. We're able to give you the visibility you need. We can give manufacturers product visibility throughout a product's lifecycle. These approaches allow for quick adapting and response when things go wrong. This will keep your customers happy and increase your profits. The benefits of using PLM combined with unique software will set you apart. We're here to help you gain visibility and keep your customers satisfied.

Contact us today to learn more!