Machine Design – A Travel Through Time

Manufacturing can be traced back to the Industrial Revolution. The Industrial Revolution changed the way that manufacturers worked all over the world. There were inventions of new machines and technology. The new production made manufacturing cheaper, faster, and more efficient. The Industrial Revolution changed manufacturing for the modern world.

In the First Industrial Revolution, which began in the late 18th century was a significant change in human history. It transitioned to industrial societies, fueled by innovations in textile manufacturing, steam power, and iron production. This period increased efficiency in the mass production of goods. The invention of the steam engine led to the increase of railways. The First Industrial Revolution was the first step in modernizing the world.

The Second Industrial Revolution is known as the Technological Revolution. This happened in the mid-19th century and was known for the adoption of electric power. This transformed the manufacturing process in steel. It led to the invention of the telegraph, telephone, television, and radio. Advancement in transportation was drastically improved leading to increased urbanization.

The Third Industrial Revolution is known as the Digital Revolution. It happened in the late 20th century with digital technology. This was the rise of the internet and digital computers. This changed the way people interacted with each other. The World Wide Web was developed. This led to the digitalization of every known modern aspect of life.

The Fourth Industrial Revolution is referred to as Industry 4.0. This revolution is known for technologies such as artificial intelligence, the Internet of Things (IoT), 3D printing, and robotics. The Fourth Industrial Revolution is expected to have impacts on society to increase quality, production, and drive economic growth.

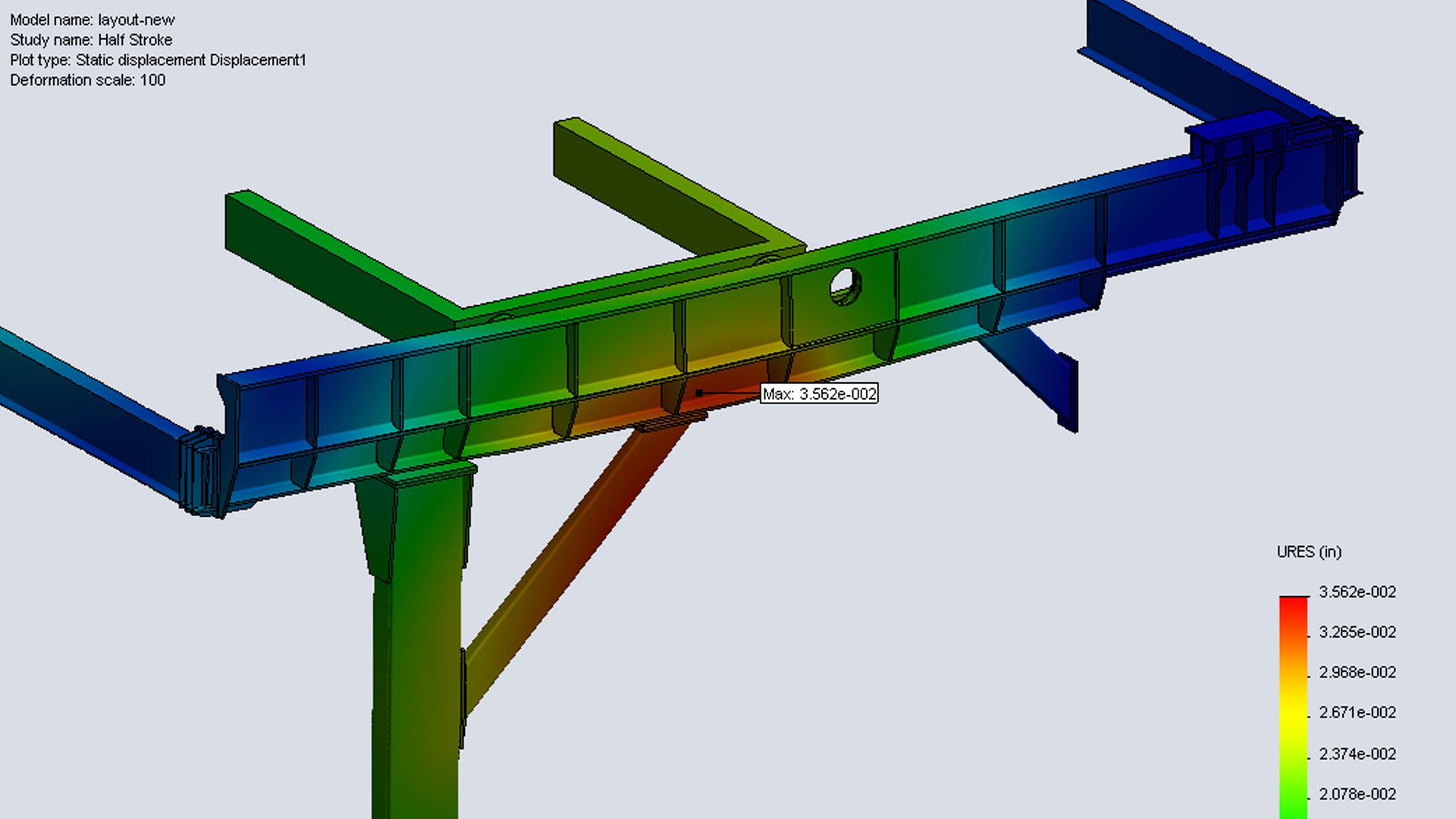

Our firm has seen these “revolutions” firsthand, and we are thrilled to be involved with Industry 4.0. We asked our President Tim Seifert what he has seen at our firm related to the Industrial Revolutions. He said “Some of our retired Engineers and a few current have were designing machines in the 40’s and 50’s. They used to walk in our CAD room with their pocket protector loaded up Pentel leads, a slide rule and drafting triangles and say this is how we used to design machines. After a few clicks our CAD Designer would spin his monitor around to show his current design cross hatched with all of the properties in a table such as density, volume, center of gravity and neutral axis. One more click and he now has high stress points marked in red highlighting VonMises, combined and maximum shear stress points.” Mr. Seifert went on to say, “A good Machine Designer utilizes the techniques that have been developed through all of the Industrial Revolutions. They incorporate the current best in class hydraulic, pneumatic, bearings gears, motors, cylinders, and couple them with the lates machine control software”.

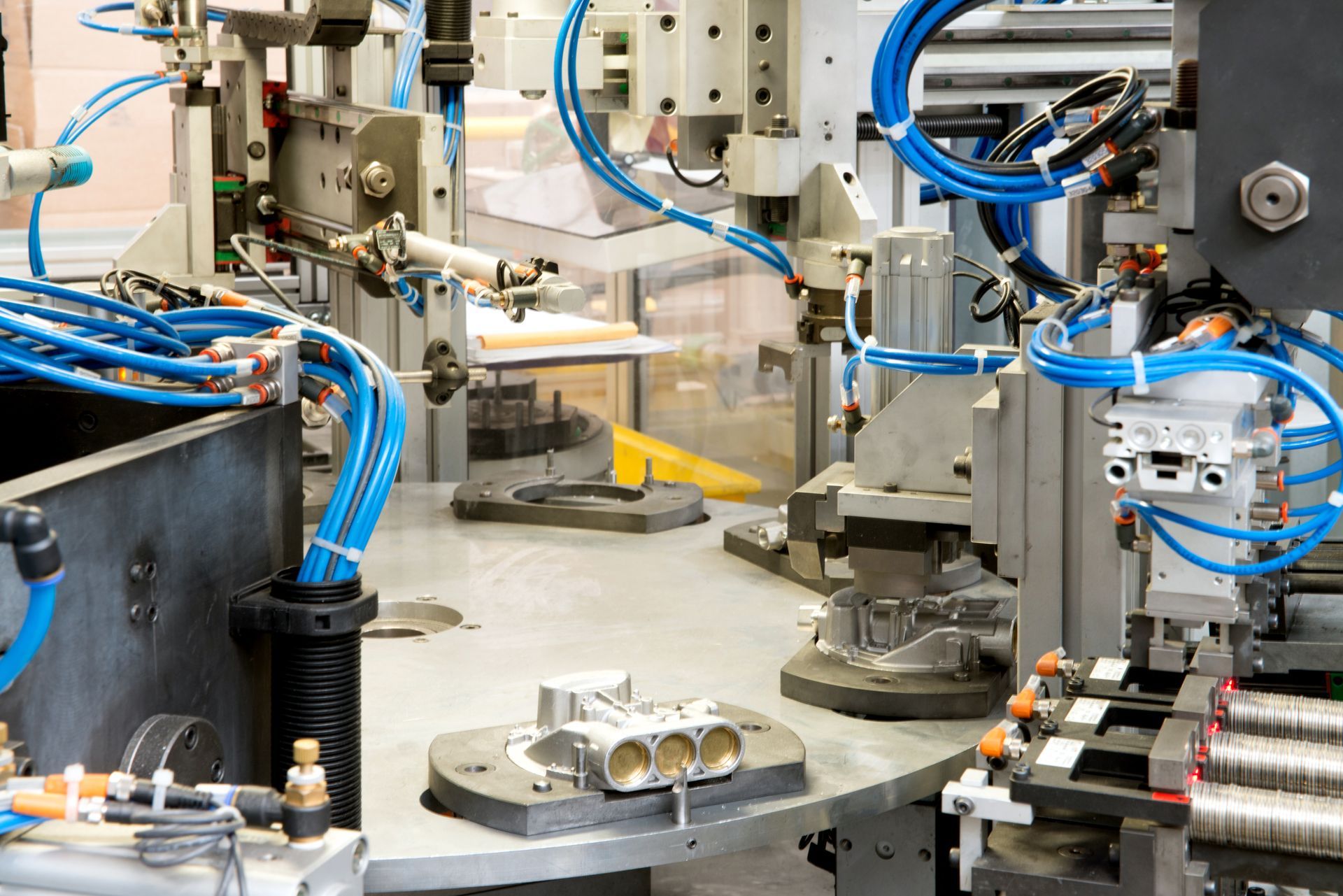

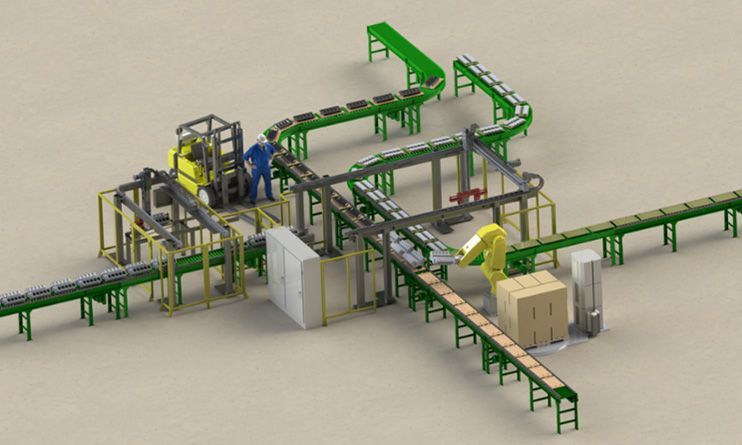

Our team of electrical and mechanical engineers and designers have candid knowledge in industries such as automotive, tire and rubber, steel mill, pulp and paper, utilities, refining, plastics, and food processing. We work with customers every day to help them upgrade their existing processes and deliver improved products more efficiently. Our electrical engineers provide a complete integration service for power and communication networks between control systems and machine components, all while following local codes and standards. We manage the integration process to validate the engineered design. Our project managers focus on keeping the project on schedule and budget, a valuable addition for design and build projects. Once field installation is complete, we check the integration process by testing hardware communication, validating software functionality, and verifying the operational requirements of the equipment. We also provide complete as-built documentation of the finished product. Our electrical engineering department can also assist you with many of your industrial automation challenges. These include designing and building custom in-line vision inspection systems, integrating robots and robotic work cells, and Industrial IoT solutions for data collection and analytics.

· PLC Automation

· PLC Connectivity

· Motion Control

· Batching Systems

· Drive Control System Packages

· Data Acquisition Software

· PID Control

· Software Support and Training

Our project teams in Massillon, Cleveland, and Nashville include Engineers, Designers, Drafters, and IT Specialists. Since 1985, we’ve executed hundreds of successful engineering projects for small manufacturers and large Fortune 500 companies. We are committed to excellence in engineering with a focus on providing our customers with innovative solutions.

Contact our Team

To learn more details about our services contact us at (330) 833-2700 or sales@seifert.com. Please visit www.seifert.com/engineering for more information on our full range capabilities