How Much Torque Do These Hinges Need?

When designing applications with doors or enclosures, getting hinges with the right level of torque is essential for safe and reliable operations, as well as good user experiences.

James Stroud

AUG 10, 2020

- Holding doors open or closed, and moving panels securely into position without secondary supports or additional components.

- Creating zero-drift motion so that when the door or cover is opened, it holds a user-defined or predefined position securely, and with one motion

- Providing the right tactile feedback to give users a good impression of the enclosure’s quality.

- Eliminating additional components (such as gas struts) or routine maintenance (retightening screws to maintain hinge resistance), thereby lowering overall costs.

- Providing a smoother, more substantial feel of opening and closing the door or to eliminate vibration.

The Right Hinge

The most common hinge is also the simplest: the free-swinging hinge for opening and closing. It offers no resistance and users must exert all the force needed to open or close the panel or rely on gravity

Beyond this basic device, hinges can be broken down into four major categories based on the torque and controlled motion they supply:

- Constant torque hinges securely hold doors or panels at any position along the range of motion.

- Detent and bistable hinges automatically go to and hold specific positions, such as 90 deg.

- Damping hinges control motion speed.

- Counterbalancing hinges make heavier doors and panels feel lighter when opened, or pop open with a simple touch.

Although many applications require only one type of hinge, traits from different categories can be combined into hinges with multi-functional positioning options.

Here are more details on each of the four types of hinges.

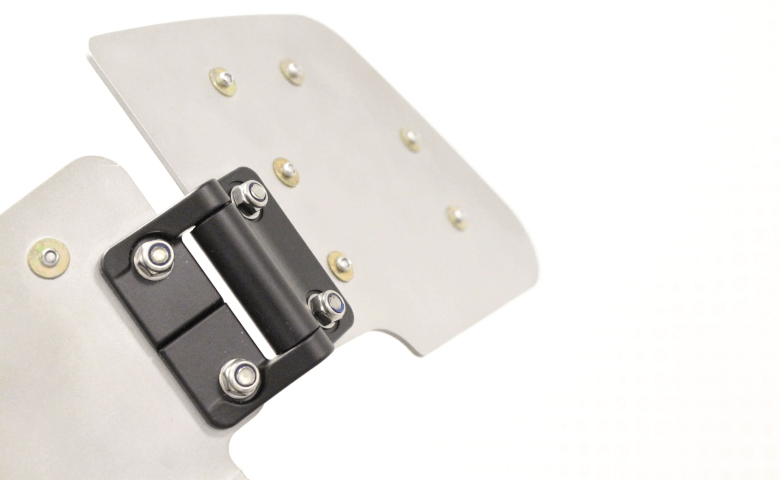

Constant torque hinges use friction between the leaf and pin to keep the hinge in the same position. Users, even casual ones, quickly learn that no matter where the hinge is at in its opening/closing arc, it always takes the same amount of force to change the hinge’s position. And it will hold the new position until someone moves it. A good example is the lid on a laptop computer. It opens and closes smoothly if someone pushes it open or closed. And if left partially or completely open, it will stay like that and not close inadvertently.

Some friction hinges are adjustable, letting users raise or lower the friction on the pin and the torque needed to move the hinge. Constant torque hinges, however, always move when a predetermined force is applied. It cannot be changed.

The checkout display installed on constant-torque positioning hinges (such as Southco’s E6 Series) can easily be tilted or turned and will remain in place despite casual touches such as signing your name or choosing a theater seat without moving. The display can be moved with one hand; there is no need to hold a button in or flip a lever.

Another type of constant torque hinges, one-way versions, provide constant torque in only one direction while providing free-swinging motion in the other. This can be useful in applications such as storage cabinets with large doors. By eliminating friction from the hinge in one direction, the door will swing open, but torque prevents it from shutting.

Detent hinges let panels or doors swing open, but at certain preset spots—say halfway open and fully open—they can lock in place with a “click” that can be felt. Users can easily push the door past a locking spot or detent and also push it out of one. These hinges are often used on lightweight cabinet doors that must stay out of the user’s way when opened.

Bistable hinges, a variation on detent hinges, contain a spring mechanism that drives the door or device to a preset angle once the door is opened. This is useful for doors, access panels or covers that must be opened to a minimum angle for easy entry.

Damping hinges let a door or compartment move steadily as it opens or closes rather than popping open or requiring the user to push it all the way closed. This smooth, steady motion is becoming widely preferred in a number of high-end applications, such as car interiors, where the driver expects an intuitive user experience. For eyeglass storage compartments and USB port carriers, for example, damping hinges add to the impression of a high-tech, finely engineered interior—a crucial element many designers seek.

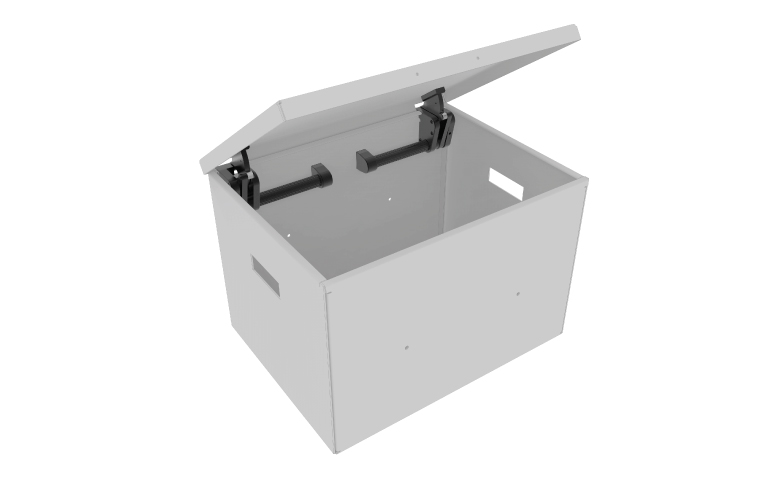

Counterbalanced hinges let heavy doors and panels be easily opened and moved into the desired position. They use spring mechanisms that store energy when the door or panel is closed. When the door is opened, the energy gets channeled to support the door and lower the user force needed to fully open the door. In other words, they lower the amount of effort needed to open a heavy door.

For applications where operators routinely open and close heavy doors such as those on industrial copiers, counterbalance hinges reduce fatigue and improve operator efficiency. For instance, a door with a symmetrical torque hinge may require 60 lb of force to fully open it. A counterbalance hinge, such as one of Southco’s CB Counterbalance Hinge series, could lower that to 3 lb.

In the past, many engineers went with gas struts to provide the counterbalancing force rather than the hinges. But those struts are prone to early failures. Counterbalance hinges provide a more economical, simple alternative. Some of the newer counterbalance hinges have a latch that supports pop-up opening. When first opened, the hinge lifts the door a few degrees, letting the user get a firmer grip on the panel to move it to the desired position.

Some of the most successful counterbalance hinges use torsion bars, cams and rollers to create and distribute the counterbalancing force. They make opening an 80-lb panel feels like a 5-lb panel, and the effort to move the panel remains the same through the entire opening or closing motion.

Key Factors

There are three key factors to consider when selecting the hinge with the right torque profile: weight, center of gravity and direction of movement.

Weight. If a panel is light enough (under a few pounds, for example), a simple hinge with no torque offers the most cost-effective alternative. As the door or panel’s weight increases, constant torque or detent hinges become more effective. The torque level in these hinges requires that users exert some force, but also prevents the door from falling.

If the door panel’s weight is between 15 and 500 lb, counterbalancing becomes a more effective option. Counterbalancing hinges stop doors from falling and make doors feel lighter. This means users are not exerting extra effort to overcome the door’s weight to open or close it.

Center of gravity. The center of gravity of a door or panel is affected by the width and shape of the panel, as well as where other components are attached to the panel. A light door with a center of gravity far from the hinge point can feel the same as a heavier door with a center of gravity close to the hinge point. For example, a tractor hood covering an engine compartment might be narrow and made of lightweight material, but because it’s so long, the center of gravity is farther out. So, it takes more torque to lift it than a box or a panel only 12 or 18 in. deep.

Some newer counterbalanced hinges use torsion bars to supply the counterbalancing force. A cam and roller mechanism distributes that force through the full arc of motion. With this type of hinge, opening a 200-lb engine hood feels like lifting a door weighing just 10 lb, and the effort is balanced through the whole range of opening and closing motions.

Direction of movement. For direction of motion, it’s important to determine whether the panel or door is hinged vertically or horizontally. If it’s hinged vertically and moves side to side, it is not working against gravity the same way as a horizontally hinged panel moving up or down. In some situations, a horizontally hinged door may need to be moved and held in place in a vertical position—for instance, to let a technician get to assemblies inside a machine. The force needed to move the door from horizontal to vertical will be higher, so a constant torque or counterbalance hinge might make more sense, especially if the technician is working underneath a door that needs to be held open.

The Right Feel

Companies that make hinges and are serious about it know that every time a person opens, closes or moves a hinged structure, they are fundamentally exerting a force. But they are also experiencing a distinctive tactile experience. For example, the erratic motion and squeaking vibrations of a rusty, old and out-of-alignment hinge does not give the user a positive opinion of the device’s quality or reliability.

The advent of more hinge technology that incorporates a range of torque options and touch point experiences gives industrial designers a new set of tools to enhance the user experience and, thus, the impression they have of the devices being used.

This torque continuum offers the opportunity to create more sophisticated solutions. Different types of hinges with different torque profiles can be combined to satisfy multiple requirements—for example, detent and damping functionality can be combined in a single hinge, so that a door easily opens to a fixed position and clicks in place, and then moves on its own in a controlled fashion to the closed position when it is pushed shut.

The key is to determine the full usage case for each application: what ergonomic effort should be expended to open, position and close a device; and what user feedback is needed or desired to accomplish this motion effectively and on a repeatable basis. The ability to fully customize the torque level allows the designer to ultimately define what the end-user experience will be. The industry’s leading hinge suppliers have extensive experience working through these usage cases to help define the optimum solution and can provide in-depth expertise to cost-effectively configure the right hinge with the right torque for each application.