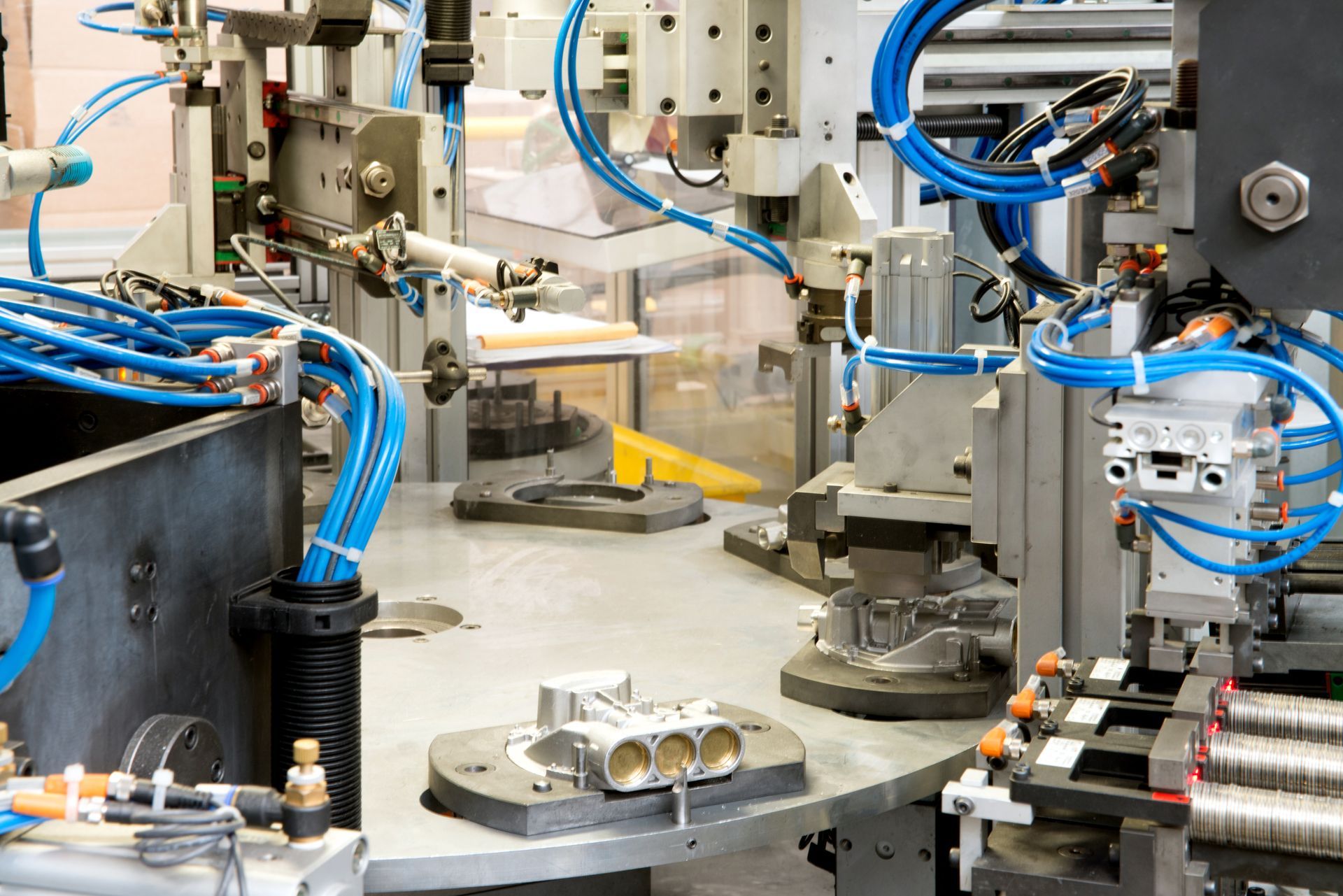

Programmable Logic Controllers (PLCs) offer a powerful and flexible solution for industrial automation, but they do come with certain limitations that users should be aware of.

Here are some common limitations of PLCs:

- Processing Power and Speed: PLCs are designed for real-time control of industrial processes, but their processing power is generally lower compared to general-purpose computers. This limitation can impact the speed and complexity of the tasks they can handle.

- Memory Constraints: PLCs have limited memory for storing program logic, data, and configuration settings. This can limit the complexity of the programs that can be developed and the amount of historical data that can be stored.

- Programming Complexity: PLC programming, especially using ladder logic, can become complex and difficult to manage for large and intricate systems. Debugging and troubleshooting complex programs can also be challenging.

- Limited Connectivity: While modern PLCs offer various communication options (Ethernet, serial ports, etc.), they might not have the same level of connectivity as general-purpose computers. Integrating with modern IT systems and protocols can sometimes be more challenging.

- Scalability: Expanding or modifying a PLC system might require significant effort and potential downtime. Integrating additional inputs, outputs, or tasks can be more complex than with other automation solutions.

- Real-Time Limitations: PLCs provide real-time control, but the determinism of real-time performance can be affected by factors such as scan time, interrupt handling, and network communication.

- Limited User Interfaces: PLCs often come with basic human-machine interfaces (HMIs) that might not be as intuitive or user-friendly as modern touch-based interfaces found in consumer electronics.

- Software Versioning: Managing software versions and updates can be cumbersome. Compatibility between different versions of PLC programming software and hardware can cause compatibility issues.

- High Initial Costs: The initial investment for PLC hardware, software licenses, and training can be relatively high, especially for small-scale applications.

- Limited Data Processing: While modern PLCs are becoming more capable, they might not be suitable for handling extensive data processing tasks or complex algorithms.