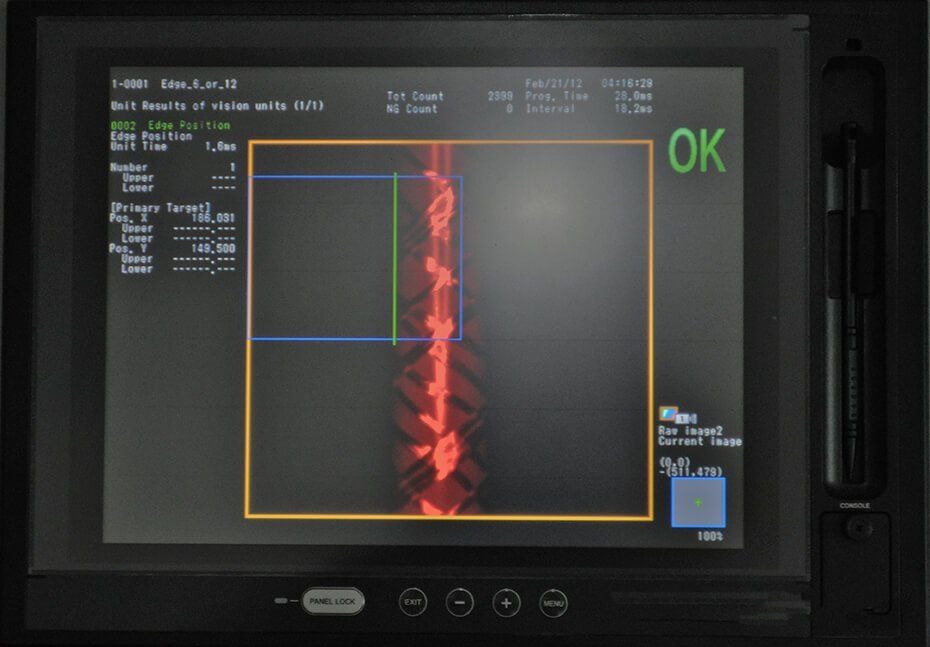

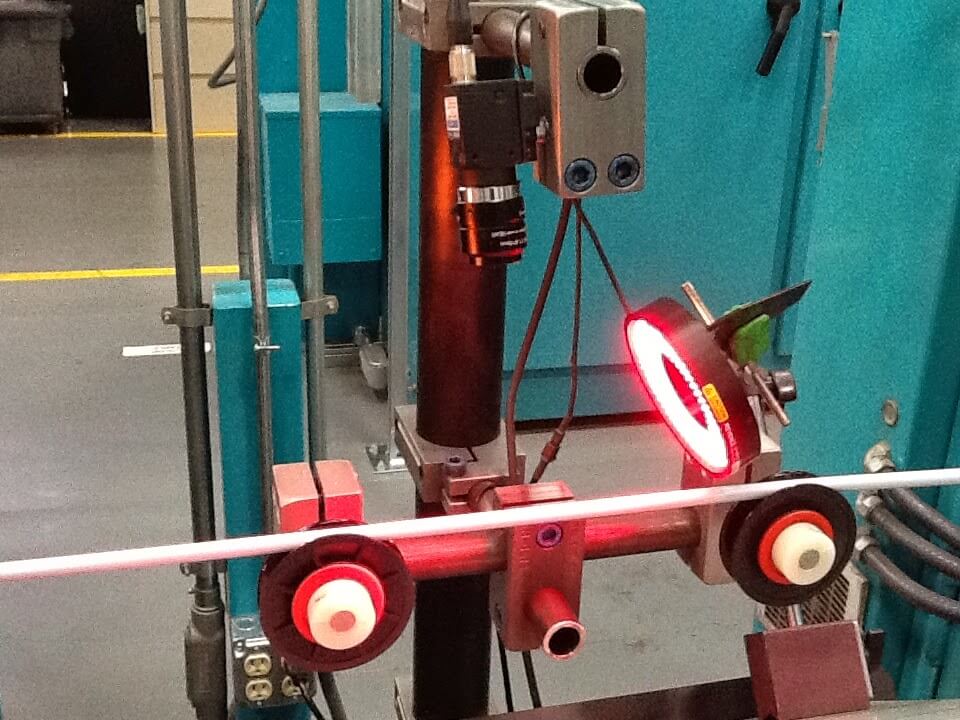

A local manufacturer of thermoplastic and fluoropolymer hose, tubing and accessories provided a unique application solution. With increased volumes of hose and tube manufacturing, reliability of existing inspection systems was put to the test. The client was using antiquated equipment for detection of construction material used in the manufacturing process. As speeds increased, a faster, more reliable detection system was required. Super-High-Speed Flexible Image Processor System was selected. This hardware, paired with custom software developed by Seifert engineers, was integrated into a state of the art inspection system, capable of validating the high speed manufacturing process.

Seifert Engineering, was called into action. Seifert engineers worked closely with the manufacturing staff for development of a high-speed, in line inspection system. Material presence and pattern recognition are key elements in the manufacturing process. Seifert engineers designed an economical, custom inspection package which incorporated a Keyence Vision system. An XG-7000 series Real-time data is now available to plant floor technicians. If manufacturing equipment fails to meet process specifications, the technician is immediately notified of the problem. The technician is able to implement a corrective action quickly; which reduces downtime and increases productivity. This joint venture has enabled them to provide quality products without sacrifice to material workmanship.

Contact Us

We will get back to you as soon as possible

Please try again later

All Rights Reserved | Seifert Companies