MECHANICAL ENGINEERS/DESIGNERS - MASSILLON, OH & NASHVILLE, TN

Services List

- CAD Services

Consulting

At Seifert Technologies, Inc., we stay up-to-date on the latest CAD software available. With over 35 CAD terminals and hundreds of customers, we learn and develop new CAD routines continually. Seifert’s core capabilities include 3D part modeling and detailing, part family creation, file translation, parametric design, automated tooling generation, and product development.

Our CAD packages include, SolidWorks Professional, Autodesk Inventor Product Design & Manufacturing Collection, Creo Parametric, AutoCAD Mechanical, AutoCAD Electrical, and NX.

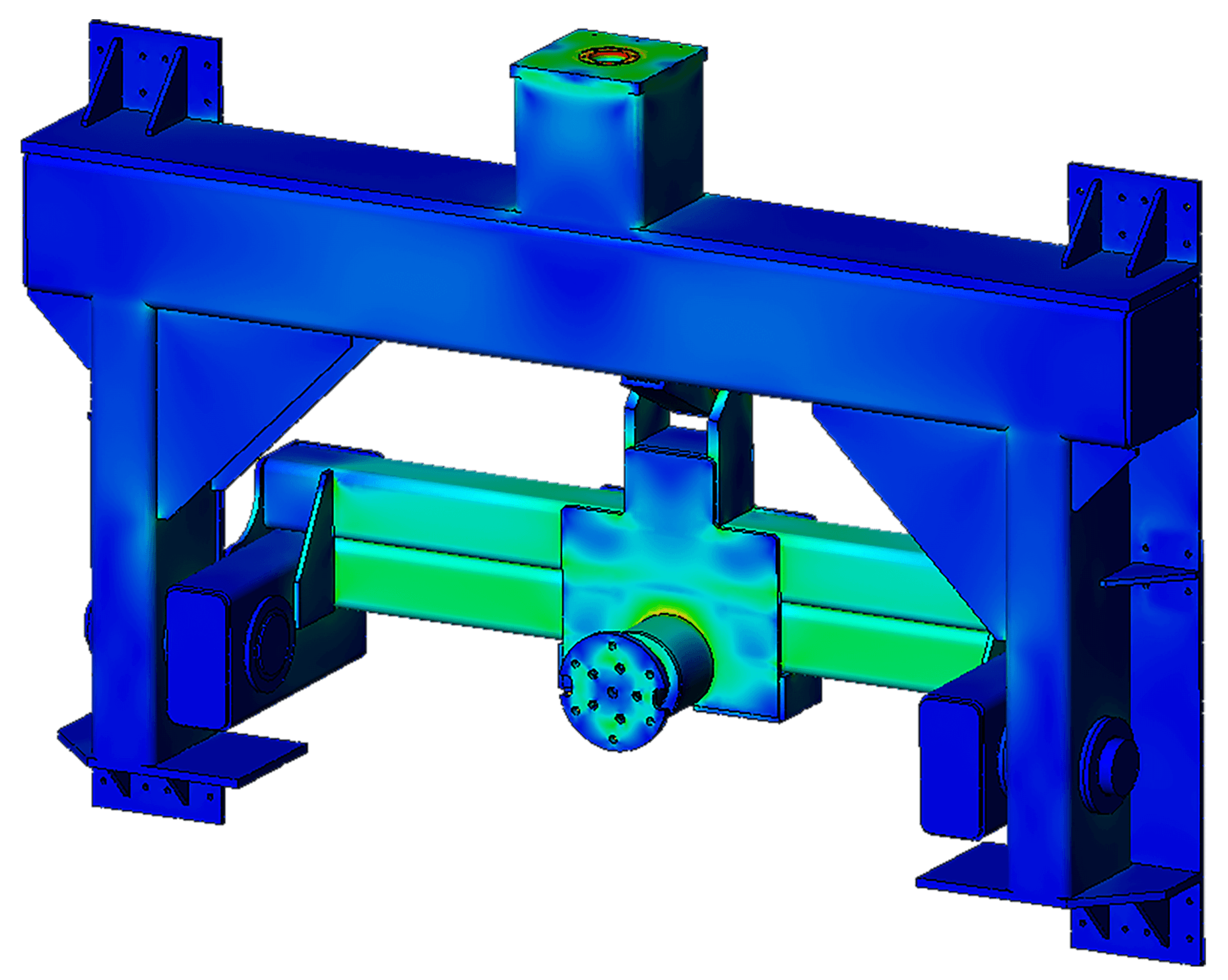

- Finite Element Analysis

Managed Services

Seifert Technologies’ FEA Services allow you to create virtual prototypes of your most complicated designs. Simulating real world conditions on your designs related to stress, temperature and vibration allows you to bring your products to market faster with better results. This process allows you to optimize your design before fabricating level one prototypes.

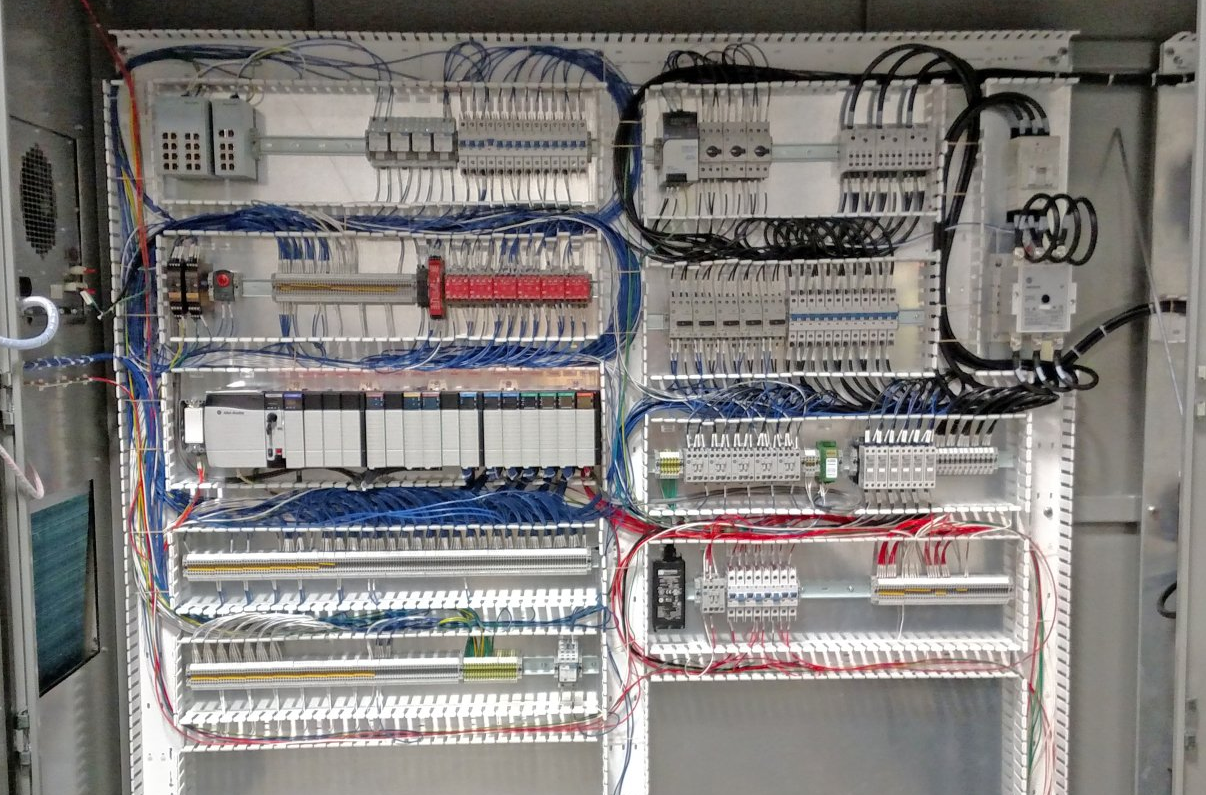

- Systems Integration

Backup and Disaster Recovery

We provide complete integration service for power and communication networks between control systems and machine components, all while following local codes and standards. We manage the integration process for validation of the engineered design and to keep the project on schedule and budget.

Once field installation is complete, we check the integration process by testing hardware communication, validating software functionality and verifying the operational requirements of the equipment. We also provide complete as-built documentation of the finished product.

- Smart Manufacturing & IIoT

Item Link

With Smart Manufacturing solutions from Seifert Technologies Inc., Our engineers will guide you through transforming your traditional, linear manufacturing system into a dynamic, interconnected organization. Whether you're just starting to investigate IIoT, or you're in the middle of integrating multiple plants, our industry experts and network of partners, will find the right solution to make you more productive.

Review Case Studies

- Iron & Steel

Hardware & Software

Seifert Technologies, Inc. Engineering Division has served companies in the steel industry from the start. We are staffed with experienced steel mill engineers to help with customized heavy duty equipment and plant services. Utilize Seifert Technologies to handle equipment retrofit and upgrading, material handling, safety equipment, cooling beds, roll stands, transfer tables, nondestructive testing, and more.

- Tire & Rubber

Our Engineering Division has a strong working relationship with the Tire & Rubber and Automotive Industries. From the start of our company in 1985, we have offered innovative design solutions for tire building equipment, tire/wheel balancing systems, large industrial conveyor belts and roofing products. Some of our capabilities include material letoff stands, tire building drums, carcass transfer, tire servers, calender upgrades, green tire handling, and tire testing equipment.

- 3D Printing & Rapid Prototyping

Software Development

In addition to our solid modeling expertise, we now have the capability to offer rapid prototyping and 3D printing to our clients.

3D printing is the ultimate just-in-time method of manufacturing. Shifting from the 2D world to physical parts accelerates product development and lowers cost. 3D parts that you can touch and feel improve design communication, so you can make better decisions faster.

Satisfied customers

We have utilized Seifert Technologies' machine design services to bolster our capacity on several occasions in the past 5 years. In our experience, Seifert's "full time" staff know their respective trades well, acclimate with our group quickly, and produce quality outputs. We would not hesitate to contact Seifert Technologies for future collaborations.

- VP, Engineering

OEM Manufacturer of Automotive Components

Button

Great company with high quality and value. Very responsive to customer needs. Highly recommended.

- President

Manufacturer of Steel Mill Equipment

Button